Roll fed-800S

Roll fed Labeling Machine

(Square and Rectangular Bottles)

Introduction

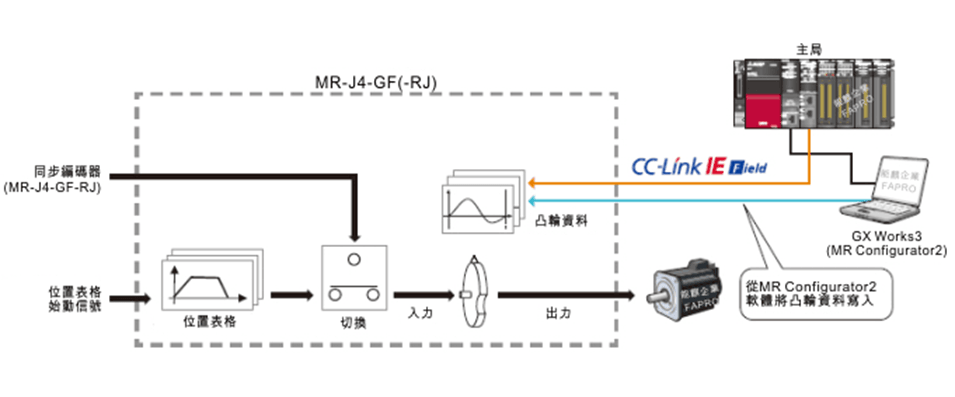

- Electronic Cam Drive

- Label Position Adjustable at Will

- Non-Traditional Cam Design

- Direct Drive by Servo Motor

- No Cam Wear from Prolonged Use

- Freely Adjustable Label Position

- 15-Minute Changeover

- One-Touch Servo Motor Homing

- Tool-Free Quick-Change Accessories

- Positioning Design

- No Manual Adjustment Needed

- Electrical Protection: IP65↑

- Dustproof

- Washable with Low-Pressure Water Jets

- Simplified User Interface

- HMI Primarily for Monitoring

- Production Initiated via Control Buttons

- No Manual Adjustments Required

- Minimizes Operational Variability

- Aging Pre-Warning System

- Torque Exceeds Threshold Alerts

- Prevents Human Error in Lubrication

- Equipped with iPad

- Dual-Operator Interface

- Single-Operator Maintenance

- iPad Video Support for Troubleshooting

- Dual-Mode Hot Melt Preheating System

- 30% More Energy Efficient

- Enhanced Safety with Timer Function

Video

Dairy Empty Bottle Labeling

125pcs/min

1250ml Square Bottle (Pre-Filling)

Dairy Empty Bottle Labeling(Side View)

125pcs/min

1250ml Square Bottle (Pre-Filling)

"More Water" Bottle Labeling

400pcs/min

850ml Square Bottle(Post-Filling)

Make Your Own Section

Add and rearrange any components you want

Equipment Specifications

- Speed

- Diameter Ø50~70mm, label length 165~230mm, 720 pcs/min (43,200 bph)

- Diameter Ø70~100mm, label length 230~325mm, 480 pcs/min (28,800 bph)

- Label

- Roll labels, inner diameter 6 inches, maximum outer diameter Ø500mm

- Label materials: OPP, BOPP

- Label thickness: 20um or more

- Label length: 165mm~325mm, width 40mm~150mm

- Photoelectric detection blank spacing: 5mm

- Container

- Round bottle diameter Ø50mm~100mm, height 100mm~320mm

- Container materials: plastic (PET, HDPE, PP, PVC), glass, and metal

- Labeling position: 10mm~165mm from the bottom of the bottle

- Glue Application

- Front and back glue width: 10mm

- Key Features

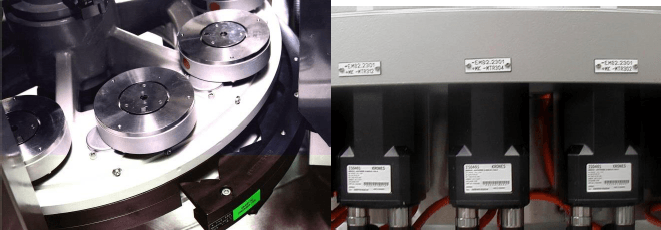

- Servo Motor Application

- Equipped with 13 servo motors, modular unit design for easy maintenance.

- Unique equipment aging warning system for real-time monitoring, reducing unexpected downtime.

- High-Efficiency Bottle Conveying System

- Extended screw design with independent servo drive for smooth bottle feeding.

- Quick-release modular design for easy adjustment and maintenance.

- Smart Control

- The upstream and downstream conveyors feature smart sensors to automatically adjust speed based on bottle

quantity. - Upstream equipped with 5 sensors, downstream with 2 sensors.

- Fully automated control system reduces changeover time to 15~30 minutes.

- HMI recipe switching enables automatic reset of upper pressure height, labeling height, and bottle pressing force

for quick changeover. - Label Cutting Unit

- Dual-knife system for precise label cutting.

- No need to replace the knife unit within the label length range of 165mm~325mm, enhancing label compatibility.

- Knife lifespan exceeds 200 million cuts, replacement time is less than 1 minute, and calibration is unnecessary after replacement.

- Vacuum Drum System

- Significantly lightweight vacuum drum.

- Front and rear glue blocks made of metal, eliminating wear issues, and can be independently removed for cleaning.

- Adjustable vacuum drum roundness for enhanced stability and precision.

- Hot Melt Glue System

- Integrated design with motor-driven precise glue control.

- Smart preheating system allows advance glue heating, reducing preparation time, enabling immediate operation at production start.

- New scraping system precisely controls transfer thickness, ensuring stable application of 0.05~0.08mm hot melt glue, effectively reducing glue usage.

- Automatic Label Splicing System

- Dual-Roll Automatic Splicing

- Seamless label switching without interruption, improving production efficiency.

- High-precision sensors detect label roll thickness and automatically reduce speed for label switching.

- Automatic label splicing with a switching time of less than 10 seconds, eliminating the need for downtime.

- Drawer-Type Automatic Splicing

- 3 to 8 drawer options for flexible label splicing sequence.

- Seamless splicing without speed reduction.

- Enables long periods of unattended operation without frequent label preparation.

- Bottle Positioning System

- Uses vision and sensors for precise label placement.

- Precisely adjusts labeling position based on bottle shape.

- Example: For milk bottles with handles, ensures uniform orientation before labeling.

- Remote Monitoring & Maintenance

- Connectable to Industry 4.0 for remote monitoring and data collection.

- Provides real-time equipment status monitoring to enhance production stability.

- Historical data analysis optimizes production processes and maintenance planning.

- Remote diagnostics and repair reduce downtime and improve efficiency.

- Safety Protection & Operational Convenience

- Safety Guard

- Transparent design, equipment stops immediately when the safety door is opened.

- Emergency Stop Button

- EMO buttons installed around the equipment for quick stopping.

- EMO buttons respond instantly to ensure safety in emergencies.

- Simple Operation

- Intelligent control panel reduces human errors in adjustments.

- Production Data Monitoring

- Real-Time Data Statistics

- Visualized dynamic dashboard and real-time monitoring panel.

- Records operational time, downtime, and upstream/downstream bottle count.

- Data analysis optimizes production processes.

Innovative Labeling

Enhancing Efficiency

Join Us!

No. 273, Section 1, Zhongai Rd, Guanyin District, Taoyuan City, Taiwan 328

TEL +886-3-4081288

FAX +886-3-4081866

lebal.taiwan@

Copyright © 2024 LEBAL Automation Intellilignece Co., Ltd. | Designed by LEBAL